Industrial Machines: Backbone of Modern Manufacturing

Manufacturing has evolved dramatically over the past century, transforming from manual labor-intensive processes to highly automated systems. At the heart of this transformation lies specialized equipment designed to perform specific tasks with precision, speed, and consistency. These powerful tools have become indispensable assets for businesses worldwide, enabling mass production, reducing operational costs, and maintaining quality standards that would be impossible to achieve through manual work alone.

The manufacturing sector relies heavily on specialized equipment to meet growing demands for products across industries. From automotive assembly lines to pharmaceutical production facilities, advanced machinery forms the foundation upon which modern production capabilities are built. Understanding how these systems contribute to efficiency and innovation helps explain their critical role in global commerce.

How Advanced Equipment Drives Efficiency in Modern Manufacturing

Efficiency in manufacturing depends on multiple factors, but machinery plays the central role in optimizing production workflows. Automated equipment performs repetitive tasks with minimal variation, ensuring consistent output quality while significantly reducing production time. Computer numerical control systems allow machinery to execute complex operations with precision measured in micrometers, eliminating human error from critical manufacturing steps.

Energy consumption represents another area where modern machinery demonstrates efficiency gains. Contemporary equipment incorporates smart sensors and adaptive controls that adjust power usage based on operational demands. This intelligent resource management reduces waste and lowers operational costs while maintaining productivity levels. Additionally, predictive maintenance systems monitor equipment performance in real-time, identifying potential issues before they cause costly downtime.

Integration with digital systems further enhances efficiency through data collection and analysis. Equipment with Internet of Things connectivity provides manufacturers with detailed insights into production metrics, enabling continuous process improvement. This data-driven approach allows businesses to identify bottlenecks, optimize workflows, and make informed decisions about capacity planning and resource allocation.

The Role of Manufacturing Equipment in Shaping the Future of Production

Technological advancement continues to reshape manufacturing capabilities, with machinery evolving to meet increasingly sophisticated production requirements. Additive manufacturing equipment, commonly known as 3D printers, enables the creation of complex geometries that traditional methods cannot achieve. This technology reduces material waste and allows for rapid prototyping, accelerating product development cycles across industries.

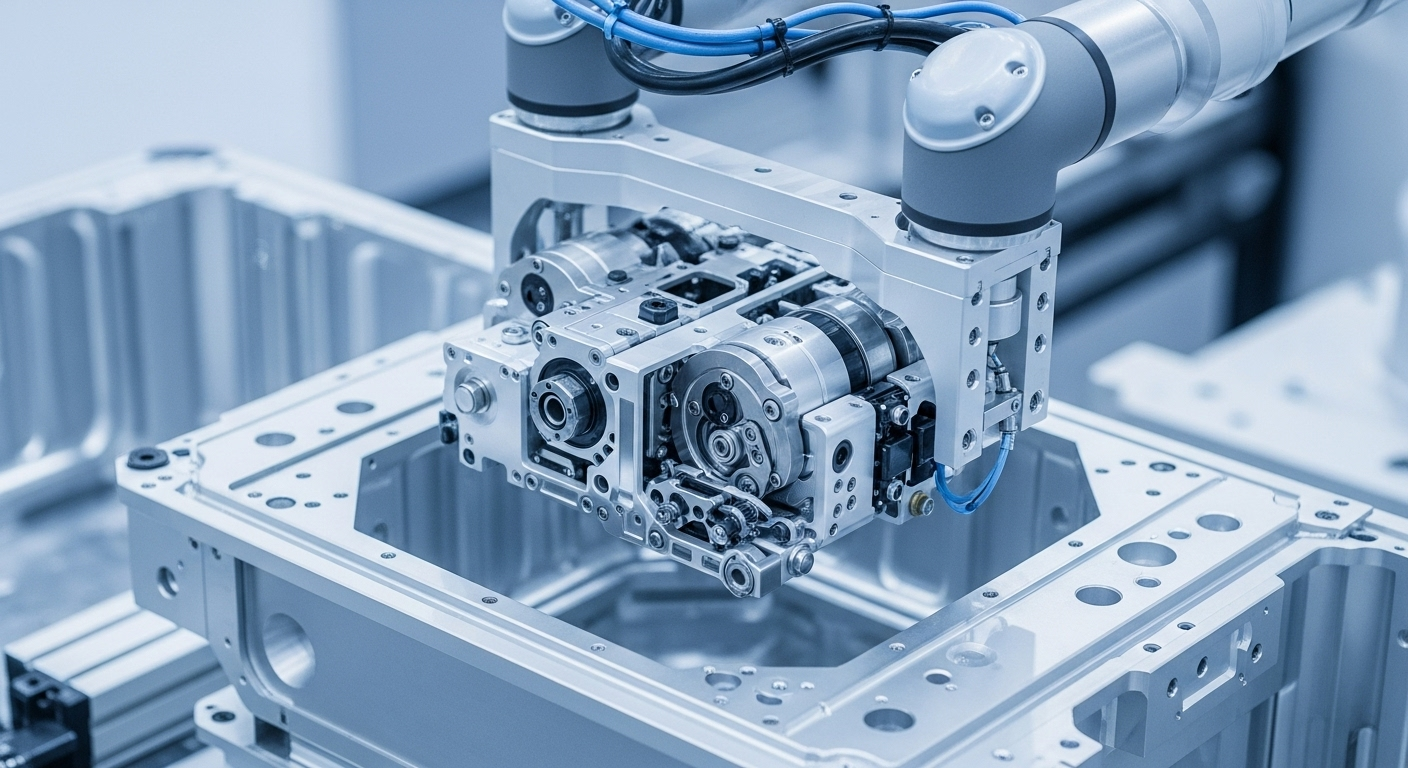

Robotics integration represents another frontier in production evolution. Collaborative robots work alongside human operators, handling dangerous or physically demanding tasks while allowing workers to focus on activities requiring judgment and creativity. These systems adapt to different products and processes through programmable interfaces, providing flexibility that traditional fixed automation cannot match.

Artificial intelligence and machine learning algorithms are being incorporated into manufacturing equipment, enabling systems to optimize their own performance over time. These intelligent systems analyze production data to identify patterns and adjust parameters automatically, continuously improving output quality and efficiency without human intervention. Such capabilities position manufacturing facilities to respond quickly to changing market demands and customize products at scale.

Why Manufacturing Equipment Is Essential for Today’s Production Success

Competitiveness in global markets requires manufacturers to deliver high-quality products at competitive prices while meeting strict delivery schedules. Advanced machinery makes this balance achievable by providing the speed, precision, and reliability necessary for modern production demands. Without sophisticated equipment, businesses would struggle to maintain the output volumes and quality standards that customers expect.

Safety considerations also make automated equipment essential for contemporary manufacturing operations. Machinery handles hazardous materials, operates in extreme temperatures, and performs tasks that would pose significant risks to human workers. This protective function reduces workplace injuries while maintaining productivity in environments where manual labor would be impractical or dangerous.

Scalability represents another critical advantage that equipment provides. As demand fluctuates, manufacturers can adjust production capacity by modifying operating schedules or adding machinery rather than recruiting and training large workforces. This flexibility allows businesses to respond to market changes efficiently while controlling labor costs and maintaining consistent product quality regardless of production volume.

How Advanced Equipment Improves Manufacturing Processes

Process improvement through machinery advancement manifests in numerous ways across manufacturing operations. Precision equipment produces components with tolerances that enable perfect fits in assemblies, reducing defect rates and eliminating the need for manual adjustments. This accuracy translates directly into cost savings by minimizing material waste and reducing the time required for quality control inspections.

Automation of material handling through conveyor systems, automated guided vehicles, and robotic arms streamlines production workflows by eliminating manual transportation tasks. These systems move materials between workstations efficiently, reducing cycle times and freeing workers to focus on value-adding activities. Integration with inventory management systems ensures materials arrive at production points precisely when needed, supporting lean manufacturing principles.

Quality assurance capabilities built into modern machinery provide real-time monitoring of product specifications. Vision systems inspect components at production speeds, identifying defects that would escape human observation. Statistical process control features track production parameters continuously, alerting operators to variations before they result in defective products. This proactive quality management reduces scrap rates and ensures consistent output that meets customer specifications.

| Equipment Category | Common Applications | Key Capabilities |

|---|---|---|

| CNC Equipment | Precision component manufacturing | Multi-axis machining, automated tool changes, micron-level accuracy |

| Robotic Systems | Assembly, welding, material handling | Programmable movements, payload capacity up to several tons, collaborative operation |

| Injection Molding Equipment | Plastic component production | High-speed cycles, precise temperature control, automated part ejection |

| Conveyor Systems | Material transportation | Continuous operation, variable speeds, integration with sorting systems |

| Packaging Equipment | Product finishing and preparation | Automated filling, sealing, labeling, and palletizing |

The integration of these various equipment types creates comprehensive production systems capable of transforming raw materials into finished products with minimal human intervention. This orchestration of machinery represents the culmination of decades of engineering advancement and continues to evolve as new technologies emerge.

Manufacturing success in contemporary markets depends fundamentally on the strategic deployment of advanced equipment. These systems provide the speed, precision, safety, and flexibility that define competitive production operations. As technology continues advancing, machinery capabilities will expand further, opening new possibilities for innovation in how products are designed, manufactured, and delivered to customers worldwide. Organizations that invest in modern equipment and integrate it effectively into their operations position themselves to thrive in an increasingly demanding global marketplace.